Overview

Eddy Current Testing (ET) is a non destructive testing (NDT) method used to detect surface and near surface defects in materials such as aluminium, stainless steel, copper, titanium, brass, Inconel alloys, and carbon steel.

ET does not require the removal of paint or protective coatings when inspecting carbon steel for surface breaking defects. This makes ET an economical and efficient NDT technique for assets.

How Eddy Current Testing Works

ET works by passing an electrical current through a probe placed on the material. This current creates a magnetic field, known as eddy currents, within the material.

When the eddy currents flow uninterrupted, the signal remains stable. However, if there is a surface or near surface defect, the flow of the eddy currents is disrupted. This disruption causes a measurable change in the probe signal.

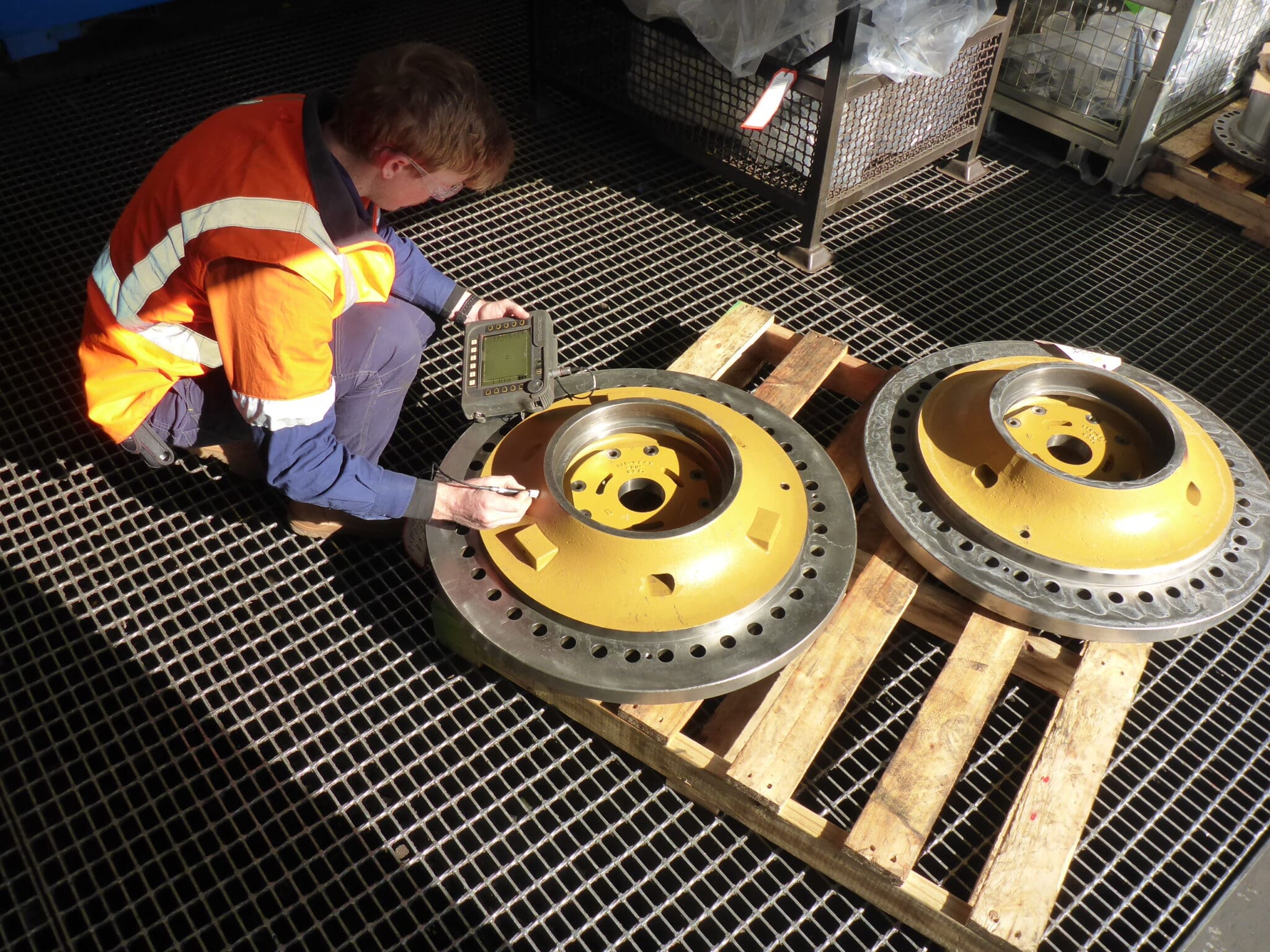

Our trained technicians interpret these signal changes to identify defects, assess their location, and determine their significance. Because the method does not require direct contact with the surface or removal of coatings, ET allows for fast, reliable inspections with minimal disruption to operations.

Common Eddy Current Testing Uses

ET is used where fast, reliable detection of surface defects is required, particularly where access is limited or coatings cannot be removed. Common applications include:

- Inspection of lifting equipment and lifting lugs

- Crack detection in fabricated and machined components

- Routine inspections on painted or coated assets

- Detection of heat damage and material degradation

- Material sorting and identification based on conductivity

This method is ideal for both field inspections and planned maintenance programs.

Advantages of Eddy Current Testing

- Sensitive to Small Cracks and Other Defects: ET is highly sensitive to small cracks, especially those perpendicular to the coil movement.

- Versatile for Various Applications: It’s used for crack detection, material thickness measurements, conductivity measurements for material identification, and heat damage detection.

- Immediate Results: The results are displayed in real-time, enabling quick decision-making.

- Non-Contact Method: ECT does not require physical contact with the material, making it suitable for delicate surfaces and automated scanning systems.

- Can Inspect Through Coatings: Thin non-conductive coatings or paint do not need to be removed, as ET can inspect through them.

- No Safety Hazards: Unlike radiographic testing, ET does not use hazardous radiation.

- Minimal Surface Preparation Required: It requires less surface preparation than methods such as dye penetrant or ultrasonic testing.

These advantages make ET a popular choice for routine inspections and quality control across many industries.

Limitations of Eddy Current Testing

As with all NDT methods, ET has limitations to consider when selecting the appropriate inspection technique for your project:

- Limited Penetration Depth: ET is mainly used for surface and near-surface defect detection and has limited depth penetration.

- Conductivity Requirements: It’s only applicable to conductive materials, limiting its use on non-metals.

- Surface Condition Effects: The method is sensitive to the surface condition of the material, and rough or irregular surfaces can interfere with readings.

- Coupling Consistency Needed: Inconsistent probe contact and liftoff can affect the reliability of results.

- Variability in Material Properties: Variations in material properties like conductivity and permeability can affect results.

- Risk of Electromagnetic Interference: ET can be susceptible to electromagnetic interference from external sources.

Our certified NDT technicians assess each inspection scenario to determine whether Eddy Current Testing is the most suitable method or if an alternative NDT technique should be applied.

ARI NDT Capabilities

We offer a range of certified NDT services across Australia, delivered by qualified and experienced technicians. Alongside Eddy Current Testing, our inspection capabilities include:

- Ultrasonic Testing

- Radiographic Testing

- Magnetic Particle Inspection

- Dye Penetrant Inspection

- Advanced NDT

With teams operating from Perth, Adelaide, Melbourne, Bunbury and Port Hedland, we have the ability to support projects nationally. ARI delivers consistent, high-quality inspection services aligned with industry standards and client requirements.

Contact Us

Send a message, or give us a call to discover how we can help.