Weld Procedures – WPS and PQR

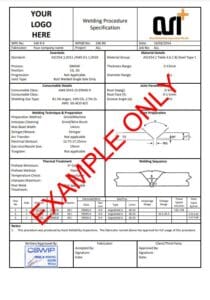

ARI have certified Weld Inspectors that can witness, record variables and create weld procedure specifications (WPS) to both Australian and International Standards. We have many qualified weld procedures in our library that can be sold as off the shelf procedures that only require the addition of your company details and your acceptance of the document before they can be used. This means you can have a code qualified weld procedure (WPS) with the supporting procedure qualification record (PQR) information within an hour, saving you the time and potential failures of trying to qualify a procedure yourself. If we don’t have the process or material type you are after we may be able to make the procedure for you.

Weld Inspection

Weld inspection is required before, during and after welding to ensure quality and integrity is achieved and then maintained throughout the entire process. ARI has certified weld inspectors who can monitor your entire process or only a part of the process, if that is all that you require. We are then able to advise whether quality and compliance are being achieved to any standard you may be working to.

Welder Qualification

Many fabrication standards require welders to be tested before welding to ensure welder ability and project quality. These tests range from bend tests, fillet break, nick break, radiographic examination, ultrasonic examination and macro examination to name a few. ARI can assist in the entire process from witnessing weld tests and then qualifying welders by performing or managing the above tests. ARI can issue range qualification certificates to any relevant standard, including ASME IX, AS3992 or ISO9606.

Contact Us

Send a message, or give us a call to discover how we can help.