Vibration Analysis

ARI provides Vibration Condition Monitoring and Vibration Analysis Services to detect machine faults at an early stage, which allows asset owners to plan maintenance measures ahead of time.

Excessive vibration levels are often used as an indication of a potential machine failure. With condition monitoring, vibration levels are measured and recorded continuously or periodically using a Data Collector. During this period, the trend in the machine’s vibration levels are analysed and if the vibration limits as per the requirement has been reached, detailed vibrational analysis will be conducted using a Vibration Analyser to be able to identify machine faults.

Machine faults that can be detected:

- Imbalance

- Misalignment

- Looseness

- Bearing and gear faults

- Lubrication problems

Benefits of Condition Monitoring and Vibration Analysis:

- Determines early warning signs of machine failure

- Identifies machine faults

- Localises affected components

- Extends machine life

- Prevents catastrophic failure and production downtime

- Ensures a safe working condition of the equipment

Thermography and Thermographic Surveys

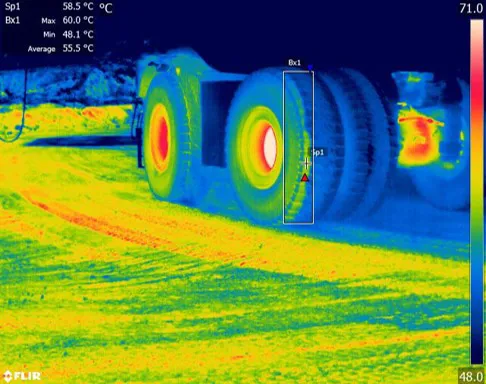

ARI provides Infrared (IR) Thermographic Surveys using state-of-the-art IR cameras to rapidly, accurately quantify and safely locate excessive heat generation in electrical or mechanical systems without the need to disrupt plant operation.

IR Thermography is commonly used as a Preventive Maintenance tool in many industries due to its non-destructive and non-intrusive approach to measure surface temperature during plant inspections. Using an IR camera, the heat generated by the components inspected is detected by measuring IR electromagnetic radiation which are then converted to electrical signals and processed to produce a thermogram which shows heat variations. With the capability of the IR camera to quantify the emitted radiation, the severity of the emissions can be evaluated by comparing it with historical operating temperatures or with IR readings of similar equipment to determine component reliability.

Applications:

- Electrical switchboards

- Circuit breakers

- Electrical systems

- Mechanical systems

- Bearings

- Mechanical couplings on rotating equipment

- Gearboxes and conveyor systems

- Process pipework inspections

- Casting and Moulding

Advantages:

- Gives an indication of a component condition

- Localises problems before failure

- Reduces machinery downtime

- Prevents catastrophic failure

- Reduces repair or maintenance costs

Contact Us

Send a message, or give us a call to discover how we can help.