Overview

Heavy Machinery or Heavy Mobile Equipment (HME) refers to the large, powerful equipment used to extract and transport minerals, ores, and other valuable materials from the earth. These machines are designed to handle large volumes of material and perform heavy-duty tasks, such as drilling, excavating, crushing, hauling, and more.

The heavy machinery on a mine site are considered critical assets because of their role in the 24/7 production process.

On-Site Heavy Machinery Inspection

Our team of experienced and certified inspectors specialises in providing comprehensive inspections for all types of heavy machinery, including excavators, bulldozers, cranes, and more. We use state-of-the-art equipment and techniques to ensure that machinery is thoroughly inspected and evaluated for any potential issues. We understand the importance of safety and reliability in heavy machinery operations. That’s why we take our inspections seriously and leave no stone unturned when it comes to identifying any potential hazards or problems with your equipment.

Workshop Heavy Machinery Inspection

If your business is responsible for the overhaul of heavy machinery components, inspecting for stress-induced cracking is of the utmost importance to ensure that when the item is put back into service, it will perform like new.

Our HME specialists have spent thousands of hours inspecting these assets and maintain very high standards to ensure they identify all defects when they are on the shop floor. If a defect is missed at this stage, it can lead to premature failure when the item is put back into service, and the repair costs will be exponentially higher.

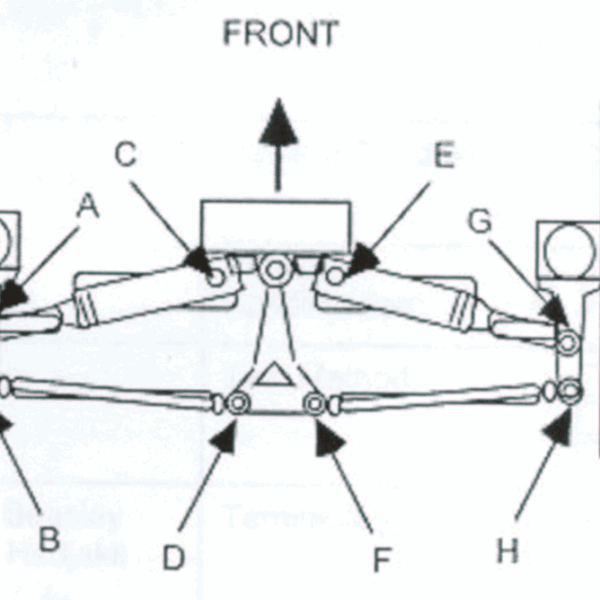

Ball Studs

Heavy earth-moving machinery, such as CAT® Mining Trucks, contain ball studs that may require ultrasonic testing every 1000 hours to determine whether they are cracked or not. The manufacturer prescribes this testing in the equipment service bulletins to prevent in-service failure, which could result in a loss of steering control.

Testing reduces unplanned downtime and haul road/pit breakdown repairs. Prior experience has shown that a strong emphasis should be placed on performing the inspection as scheduled. ARI has developed the technique using custom components to reduce the inspection time from 45 minutes to 15 minutes per truck.

This inspection is critical to the reliability of these vehicles and should only be performed by experienced and certified professionals.

Contact Us

Send a message, or give us a call to discover how we can help.