Overview

ARI delivers expert pressure vessel inspection, tank inspection, pressure equipment design verification, and weld inspection. Our competent inspection team is backed by an engineering team that can provide additional services, such as engineering assessments or finite element analysis. This integrated capability means ARI is trusted to be the inspection partner for a number of sites across Australia. Additionally to this, on request, ARI performs vendor inspections internationally for items destined for Australia.

In Service Pressure Vessel Inspection

Pressure Vessel Inspection is legislated at a State and Federal level in accordance with AS3788 to ensure continued safe use. ARI provides competent pressure vessel inspectors who are API/AICIP/ASME certified and experienced in working with a vast range of vessels with different hazard classifications.

Portable Compressors

Any air receiver at a workplace must be inspected as stated in the Occupational Safety and Health Act making it a legislative requirement. The compressor inspections are required to be performed by in-service inspectors of pressure equipment, such as our certified inspectors. The frequencies for these inspections are normally two yearly as per AS3788 Table 4.1.

The reason for this all inclusive requirement is because the definition of Pressure Equipment requiring inspection, being any pressure vessel with a hazard level of A,B,C,D as per AS4343. This requirement essentially captures all air receivers in the workplace, regardless if they require individual item registration.

Winery Pressure Vessels

The process of producing wine requires several types of pressure vessels, these include but are not limited to, grape presses, air receivers and chillers. These pressure vessels fall under the OH&S Regulations definition of “Pressure Equipment” requiring inspection, being any pressure vessel with a hazard level of A,B,C,D as per AS4343.

ARI can assist with all pressure vessel owner responsibilities by inspecting pressure vessels, calculating hazard levels and assisting owners with item registration requirements.

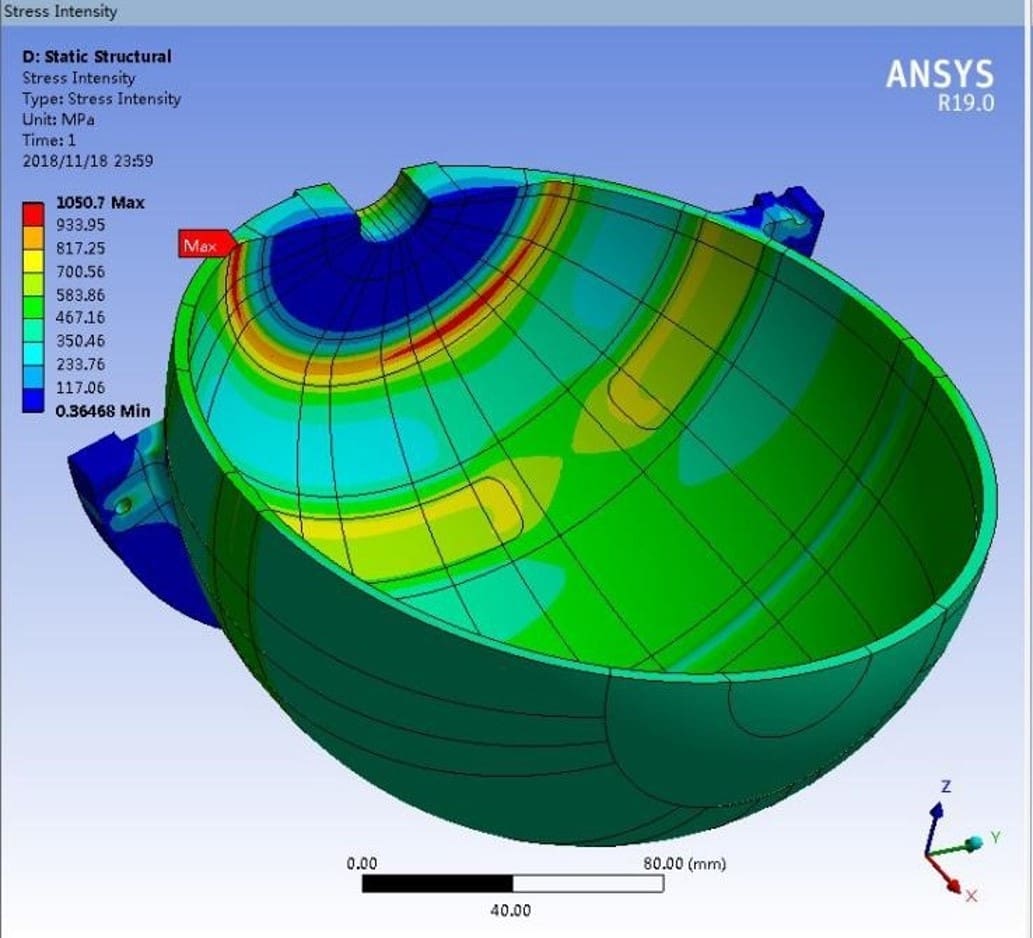

Pressure Vessel Design & Verification

Our experienced engineers can design and verify pressure vessels to API 510, ASME VIII and other suitable design standards. Additionally, ARI can manage the entire application process for a pressure vessel design approval number with the State or Territory regulator of your choice. We have the capability to design, verify and determine the fitness for service of pressure equipment utilising Australian and International standards. This is done by either calculation or finite element analysis (FEA) for complex designs and sometimes a combination of both.

Tank Inspection in Accordance With API653

Bulk storage tanks are critical assets for businesses across a wide range of industry sectors. ARI provides API-653 or similar internal and external tank inspection solutions to satisfy surveillance and compliance requirements.

Inspectors for API 653 Aboveground Storage Tanks are required to have a comprehensive knowledge base and undergo recurring training, specific to the examination of storage tanks.

ARI has full capability for tank inspections, including MFL floor scanners, tank settlement laser equipment, and ultrasonic robotic crawlers.

Read more about Storage Tank Inspection Services.

Above-ground storage tanks require regular inspection and maintenance to ensure safe operation, reduced risk, and regulatory compliance.

SOLUTION

ARI provides API-653 or similar internal and external tank inspection solutions to satisfy both surveillance and compliance requirements.

End-to-end assurance or code compliance services include the following assessments:

External visual inspection: A detailed examination of the tank’s external surfaces, including the shell, roof, and foundation, to identify signs of damage, corrosion, or other defects.

Internal visual inspection: A detailed examination of the tank’s interior surfaces, including the floor, walls, and roof, to identify signs of corrosion, pitting, cracking, or other defects.

Tank bottom evaluation via Magnetic Flux Leakage: A thorough examination of the tank’s bottom to identify any signs of corrosion, cracking, or deformation.

Ultrasonic thickness testing: To measure the thickness of the tank’s shell, roof, and floor to identify any areas of thinning or corrosion.

Settlement survey: A survey of the tank’s foundation to measure any settlement or movement that may have occurred and to identify any potential structural issues.

Leak testing is a test to detect leaks in the tank’s floor, roof or shell using a vacuum pressure unit.

Weld inspection: A visual and non-destructive testing examination of new or existing welds in the tank’s shell, roof, and floor to identify any defects.

DELIVERY

ARI can provide the inspection and evaluation of a wide variety of above-ground storage tanks, including an engineering fitness for service, recommended best practices, as well as advice on remediation and future recommended inspection frequency.

Contact Us

Send a message, or give us a call to discover how we can help.

FAQs

What is a pressure vessel inspection?

A pressure vessel inspection is a systematic assessment of pressure equipment to ensure safe and reliable operation. ARIs certified non destructive testing (NDT) technicians carry out visual inspections, thickness measurements, weld assessments, and NDT methods to identify defects. These inspections comply with Australian standards, including AS3788.

How often should pressure vessels and tanks be inspected?

The frequency of inspections depends on equipment type, operating conditions, and statutory requirements. Generally, in-service inspections are conducted annually or at intervals specified by AS3788. ARI can tailor inspection schedules for vessels and tanks in Perth, Adelaide, Melbourne, Bunbury, and Port Hedland to meet compliance and operational needs.

What does a tank inspection involve?

Tank inspections assess structural integrity, material degradation, and safety compliance. ARI’s inspections include internal and external assessments, thickness testing, weld inspections, and NDT techniques where applicable. Comprehensive reports detail any findings, allowing maintenance teams to make informed decisions.

Are in-service inspections mandatory for pressure vessels and tanks?

In Australia, in-service inspections are required under State and Federal legislation to ensure ongoing compliance and safe operation. ARI’s inspections satisfy all statutory requirements and help clients demonstrate regulatory compliance.

Which industries require pressure vessel inspections and tank inspections?

Inspections are critical across mining, oil and gas, chemical processing, manufacturing, power generation, and infrastructure sectors. ARI provides nationwide inspection services from offices in Perth, Adelaide, Melbourne, Bunbury, and Port Hedland. If you’re unsure, get in touch, and we will be more than happy to discuss your requirements.

Do inspections include non-destructive testing (NDT)?

Yes. ARI integrates certified NDT methods such as Ultrasonic Testing, Radiographic Testing, Magnetic Particle Inspection, and Dye Penetrant Inspection into pressure vessel and tank inspections where appropriate. This ensures early detection of defects without compromising the equipment.

What happens if defects are found during an inspection?

If defects or areas of concern are identified, ARI provides detailed reports. Clients can plan repairs, mitigate risks, and maintain compliance. Engineering assessments or finite element analysis can also be provided when needed.

Can ARI perform inspections nationwide?

Absolutely. ARI provides in-service pressure vessel inspections and tank inspections across Australia. Our local teams in Perth, Adelaide, Melbourne, Bunbury, and Port Hedland ensure timely, compliant inspections for routine assessments, shutdowns, and critical asset evaluations.

Can ARI inspect newly manufactured vessels or tanks?

Yes. ARI also performs vendor inspections for new equipment destined for Australian sites. These inspections verify compliance with design and statutory requirements before installation, ensuring safety and performance from day one.