Conventional Ultrasonic Testing (UT) uses a probe comprised of a piezoelectric element capable of generating high-frequency acoustic waves that travel at a specific velocity dependent on the material. The UT instrument produces an A-Scan that visually represents the ultrasonic signal travelling through the component. Analysis of this A-scan display allows for the evaluation and interpretation of the specimen under examination.

UT is primarily used for Thickness Measurement, Weld Inspection, Ball Stud Testing, and Lamination and Corrosion Detection. It is a cost-effective, fast inspection technique that can determine the acceptance or rejection of a test object based on a reference code or standard.

ARI was featured in the Evident InSight Blog as using best practice to conduct Ultrasonic Thickness measurements using their instrumentation.

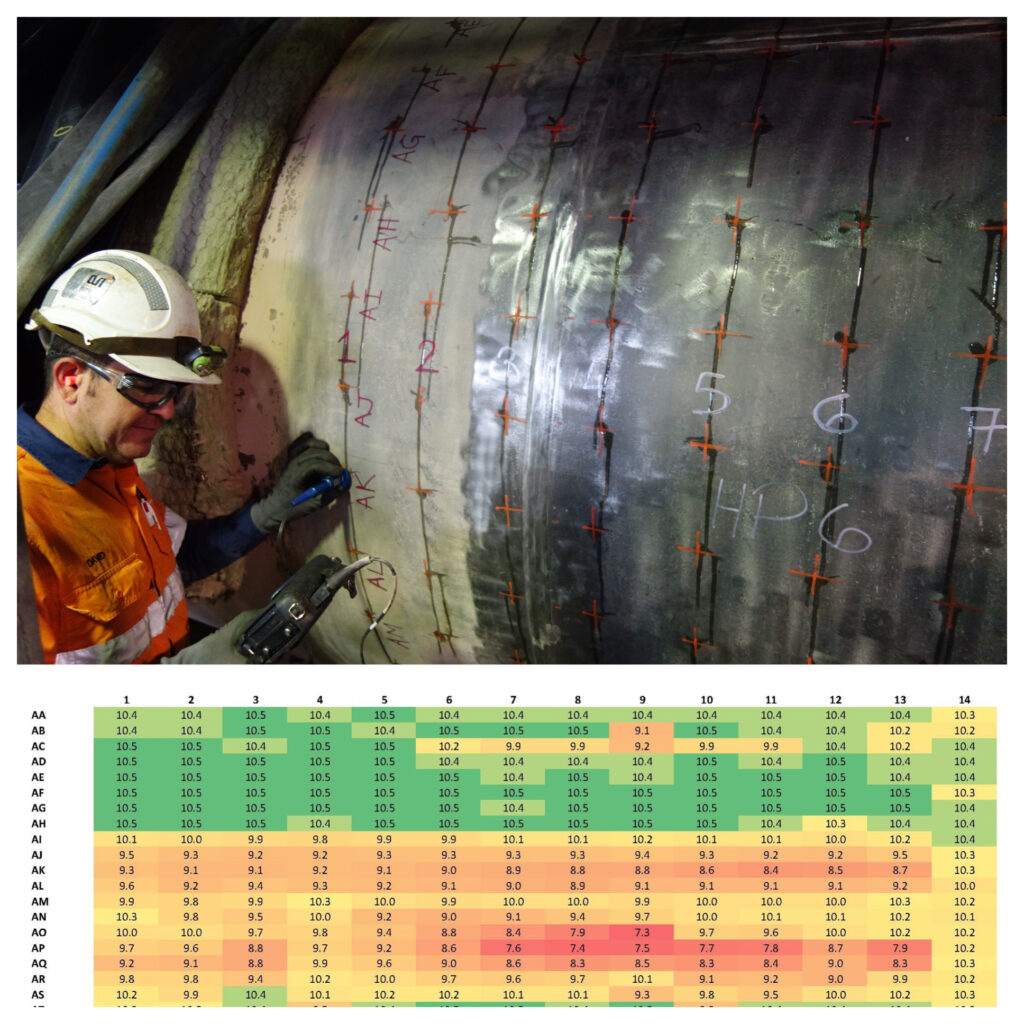

Image: Grid scanning technique for measuring wall thickness using UT (from Evident InSight Blog)

Contact us sending a message or give us a call to discover how we can help.

ARI delivers professional services in pressure equipment inspection, weld inspection, and non destructive testing.

Asset Reliability Inspections © 2025 All Rights Reserved